Matrix Touch - Central Control

Matrix Touch advanced touch screen display for easy programming and real time monitoring of production process status, as well as in graphical form.

MATRIX TOUCH on-board Terminal is the latest BTSR technology allowing advanced BTSR sensor programming & monitoring of the production line. Developed with Touch-screen and Multi-language technologies for user-friendly operation, MATRIX TOUCH is provided with Wifi & Ethernet interface. The machine operator can easily download & upload indentification data, as well as program the sensor parameters

-

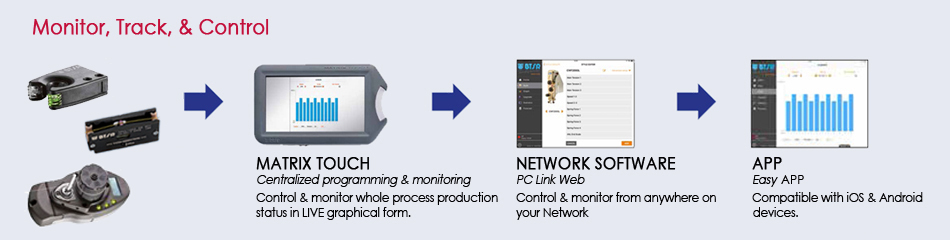

Compatible with BTSR APP EasyFeeder & PC Link Web Industry 4.0 Tools.

-

Easy & quick sensor identification thanks to the Automatic Numbering Procedure (BTSR Patent)

-

Real-time display of single working status.

-

Data collection & storage of anomalies detected by each single sensor.

-

Data Report with analysis of technical faults (number & type)

-

Maximum precision - possibility of programming the sensors technical features according to the type of yarn to be processed.

-

Absolute flexibility - possibility to quickly change the sensor technical features according to the yarn / process typology.

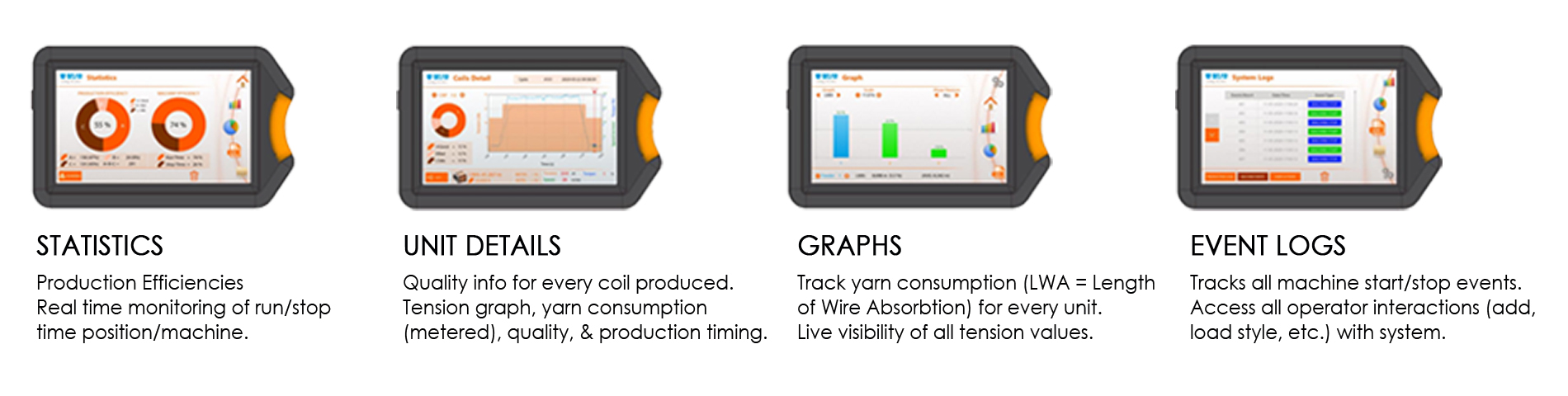

PRODUCTION TRACKING - As with all our sensors, the TOUCH MATRIX provides LIVE production tracking which can connect to our Network software, giving you automation at multiple levels. This cloud based system monitors & tracks all yarn stops, breaks, & doffs for showing production/waste in real time. It can also connect to any PC or smartphone to give you instant visibility of your production from anywhere in the world.

Automated Stops & Alerts - BTSR's automated alert system makes the operator immediately aware of any problems & helps the operator quickly identify where the stop is located.

24/7 Operator Management - BTSR let's you manage your employees when your not there. You can effectively monitor & track detailed performance data for every operator shift, & day.

LIVE Production Status - Know your exact production, waste, & efficiencies 24/7. You can immediately react rather than waiting until the next day for production calculations. View from anywhere on your network or smart phone.

Yarn Consumption Status - With any BTSR system that provides metering (MTC, MSC, Feeders), the TOUCH MATRIX will show LIVE running totals in Meters/Yards per package & total for every position, machine, & plant. It will calculate the amount of production & waste by exact length in real time.

Additional Info & Videos